Jerry Lee Oleson

Well-known member

So does anyone make an aftermarket FI system for a Spridget? Or 1 1/4 individual throttle bodies ?

Both you and Mike alluded to this...let's all remember that the allowance for conversion to EFI is to a throttle body injection only (see reg at the bottom). Other than within that throttle body, you will NOT have the opportunity to be dyno-testing injectors locations are anything like that. So that's a moot point.chois said:This is not to say that injector timing, or injector location won't make a difference, but it may not behave the way you intuitively expect.

Which, coupled to the above, is why I kinda see this as "no big thang"....you will create more consistent performance over a wider range of conditions, once you get the tune refined to a certain point...Remember that a well tuned carb actually runs very well, and there is certainly no "timing" of fuel events with those.

Darryl Saylor said:Found these 31 mm throttle bodies.

http://www.yuminashi.com/-pcx125-31mm-throttle-body/

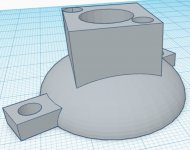

I was wondering if you could make a cap to go where the piston is on the su carb where the injector mounts. You would have to plug the hole where the jet comes thru. Take this with a grain of salt because I'm not really sure about any of this

suficap.jpg

chois said:That is some interesting research for sure. Thanks for sharing.

One thing to not get too wrapped up around when considering this is thinking about injection events as being timed to valve open time.

There is a LOT physically going on with the intake air, and the fuel being introduced, and the harmonics in the columns of air/fuel going down the runners - and it doesn't behave the way we initially imagine.

Remember that a well tuned carb actually runs very well, and there is certainly no "timing" of fuel events with those.

This is not to say that injector timing, or injector location won't make a difference, but it may not behave the way you intuitively expect.

This is a case where getting the big things right is important, and the little things will generally be found on the dyno, or with good data, and analysis from track sessions. One thing is for sure, if you move to a programmable system to control fuel you will create more consistent performance over a wider range of conditions, once you get the tune refined to a certain point.

:cowboy:chois said:Greg - those look super cool...I'm getting 914 envy over here.